Lead-Time Optimization in the Current VUCA Environment

The COVID-19 pandemic has brought significant disruption to the manufacturing sector in 2020. As a result, the global economy is going through a severe supply shock phase with high volatility, uncertainty, complexity and ambiguity (VUCA). In the last three months, federal and state governments in most major economies have started relaxing the lockdown restrictions and released billions of dollars in stimulus packages to revive the manufacturing sector and control bankruptcies among the SMB segment.

A significant percentage of the global workforce is still operating from their home office and keeping themselves semi-quarantined. Since April 2020, eCommerce has grown in most parts of Western Europe and North America, and there is a significant amount of demand volatility in the market. In current circumstances, it’s challenging for manufacturers to have a strong handle on their inbound and outbound order management, and have a short lead time for their marketplace, retail, and end consumers due to persistent disruption in the downstream supply from Tier-1 suppliers, and consistent challenges with owned and 3PL carriers.

Currently, we are working with multiple clients in the CPG, FMCG and Technology verticals, delivering Order Lead Time Optimization for their Make to Stock (MTS), Make to Order (MTO) and Configure to Order CTO) products. The objective is to control the Fill Rate, Safety Stock Levels, Service Levels and CSAT across different product categories and customer segments for their Retail and D2C customers. Below mentioned are some of the strategies we have deployed in the last four months for one of our large technology customers, which helped them reduce lead time, and meet their desired service levels for their Retail and D2C customers:

1. Demand Sensing

The client has been producing a daily statistical forecast at the item-location level for their MTS products measured on a 7-day lag period, and aligning their available supply to an improved demand signal by leveraging our Demand Sensing model powered by Course5 Discovery. In addition, the S&OP Manager reviews the S&OP plan every week and uses the demand sensing forecast during team meetings to make mid- to long-term capacity decisions. The group reviews market deviations and makes decisions on demand shaping (an operational supply chain management (SCM) strategy where a company uses tactics such as price incentives, cost modifications and product substitutions to entice customers to purchase specific items.) based on the supply chain strategy and compares the demand sensing forecast with the mid-to-long term strategic forecasts coming from their APO (Advanced Planner and Optimizer) system. This process enables them to ensure short lead times by making optimal near-term production line schedules and near-term load-capacity decisions. Here are some of the benefits our clients have experienced using Demand Sensing:

- A significant (>35%) reduction in forecast error at the weekly item location level

- Reduction in demand latency (the period of time to understand demand changes) from monthly to weekly; this helped their Logistics team reduce safety stocks and improve responsiveness to demand

- Resolution of past inventory problems as a result of better plant scheduling

- Reduced customer service issues

2. Increased Safety Stock Levels

CTO products usually have a lot of variability in their order lead times, which is generally caused by inaccuracies in the demand forecast, lower than optimal safety stock levels, challenges with Tier-1 suppliers, and longer distance between the Plants and Distribution Centers. Considering the consistent challenges with Inbound and Outbound Logistics, and shortage of supplies from Tier-1 suppliers, the client decided to maintain 15% – 20% higher Safety Stock Levels for the critical components (Processors, Flash Based Memory, SDDs, and VGA Cards) that go into CTO products. To determine the optimal safety stock levels considering the current demand volatility, we leveraged the Safety Stock Simulation in the Course5 Discovery Model Factory. This strategy led to an increase in the inventory carrying cost but avoided the service level and lost customer issues in this volatile time.

3. Increased Warehouse Capacity through Leasing

Due to consistent challenges with the Motor-Truck and Air-Cargo capacity, and the rising transportation cost for last-mile delivery, the client invested in the leased regional warehouses closer to the cities with higher demand so that lead time reduction can be ensured and the desired service levels and CSAT targets are met. To identify the additional capacity, we worked closely with the Demand & Supply Planning lead and the head of Logistics and Customer Service to optimize the current network design, and identify new warehouse locations in the high demand cities.

4. Leveraging Retail Partners as Fulfillment Centers

As an experiment, the client also started leveraging the local retailer partners as fulfillment centers for their MTS orders placed online in select cities. So far, the results are satisfactory, and it has positively impacted customer satisfaction levels. This strategy is a wonderful opportunity for up-scaling but would require a much tighter collaboration among different echelons in this integrated supply chain.

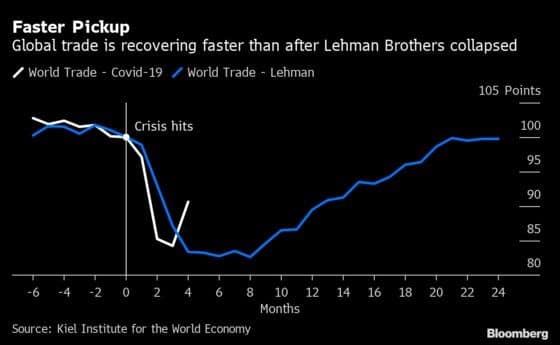

According to experts, the global trade recovery has started in Q3’2020, and it’s happening faster than the expectations. Global trade recovery is faster than the 2008 financial crisis and shipping volumes are already back at levels that took more than a year to reach following the collapse of Lehman Brothers, hinting at a V-shaped recovery, Germany’s Kiel institution’s President Gabriel Felbermayr said1.

In the end, we are expecting that these positive signals of recovery will impact lead time reduction for both inbound and outbound logistics in the coming quarters, and deliver better service levels and customer satisfaction to both Retail and D2C customers.

References:

1 https://fortune.com/2020/08/31/global-trade-recovery-2020-covid-coronavirus-2008-global-financial-crisis/

Sushant Ajmani

Sushant is a seasoned digital analytics professional who has been working in the industry for over 23 years. He has worked with over 180+ global...Read More

Don’t miss our next article!

Sign up to get the latest perspectives on analytics, insights, and AI.